PTFE Seals

NewDealSeals has been advising companies on the use of PTFE, drawing on the extensive knowledge gained from different industries. In spite of its remarkable properties, virgin PTFE (unmixed PTFE) has limited use for applications where high mechanical loading is required.

Furthermore PTFE is not elastic as rubber compounds. For this reason, PTFE seals are provided with a slight amount of tension in relation to the installation diameter. Reliable contact force is guaranteed by an elastomer-expander shaped as an O-ring or rectangular ring or a stainless spring. On this page the most common PTFE Seals are briefly described.

PTFE Products

Spring Energized Seals

The Synering® system is an advanced sealing concept designed to meet extreme demands regarding temperature, medium, etc. which cannot be covered by conventional sealing compounds.

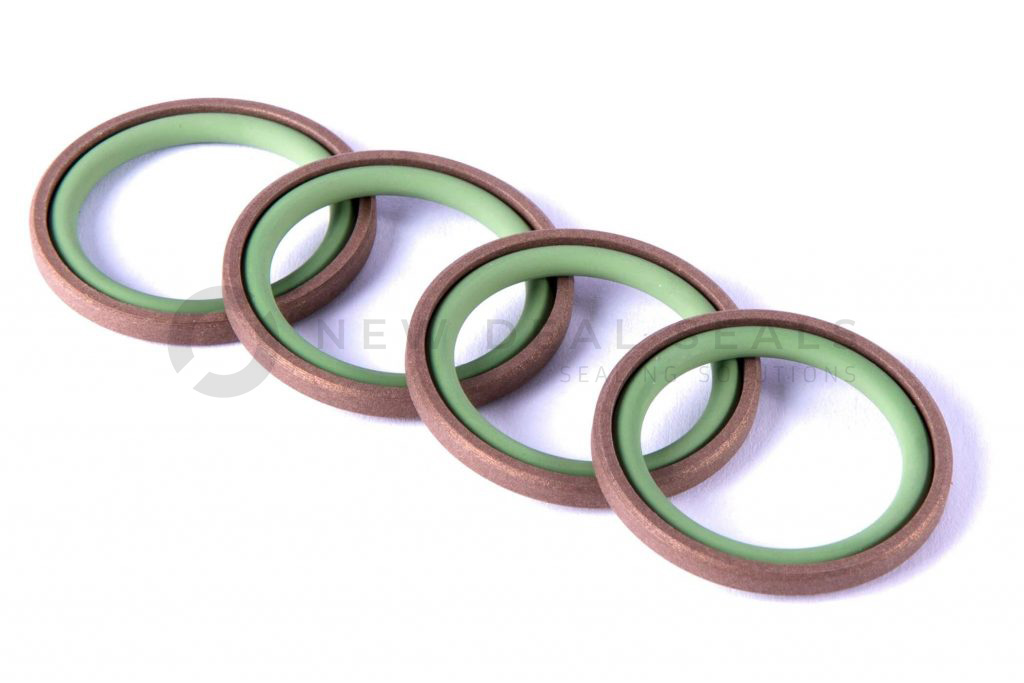

Piston Seals

The Piston Seal consists of a single-acting PTFE piston sealing ring and an O-ring. They are combined as a single unit and are appropriate for single- acting pistons in hydraulic cylinders.

Wiper Seals | Scraper Seals

Wiper seals function to prevent dust, dirt, grains of sand and metal dwarf from penetrating into axially moving rods and plungers.

Rod Seals

The Rod Seal consists of a single-acting PTFE rod sealing ring and an O-ring. They are combined as a single unit and are appropriate for rods and plungers in hydraulic cylinders.

Guide Rings | Wear Rings

The guide ring or wear ring guides a hydraulic cylinder piston and rod and absorbs lateral forces. Metal to metal contact between the moving parts of the cylinder.

Rotary Seals

Rotary seals are used in applications with oscillating or rotating movements in order to retain liquid lubricants and to prevent the penetration of dirt and water.

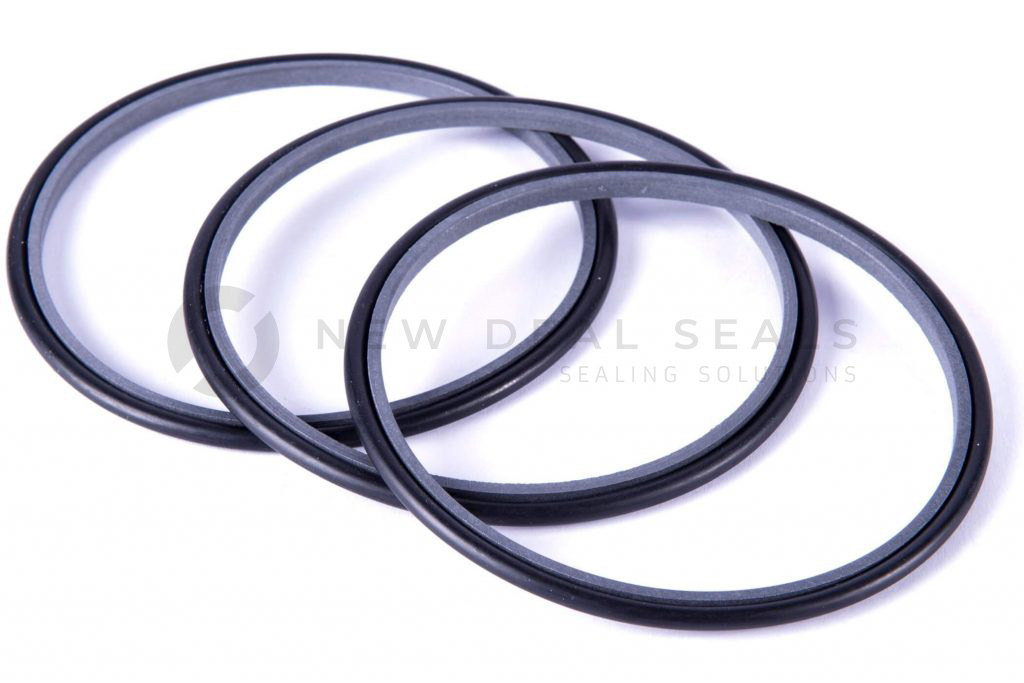

Back-up Rings

Back-up rings are used for static and dynamic applications in connection with O-rings, to prevent extrusion of the O-ring into the diametrical clearance.

Our Range of PTFE Materials

Relevant PTFE Materials

The PTFE compounds are available standard as 100% PTFE (Virgin), but can also be filled with various percentages of glass, molybdenum disulphide, polymers, carbon, carbon fibre, graphite and/or bronze. NewDealSeals supplies PTFE seals in accordance with various standards (ISO 3601) and with various approvals (KTW, USP, NSF 51 61, WRC, WRAS, FDA, R67 01). Available in more than 50 different compounds, subdivided into the following materials:

- PTFE (Teflon®, Turcon®)

- PCTFE (Kel-F®, Neoflon®)

- PEEK (VICTREX®)

- PA6 (Nylon®)

- POM

- PE

- PET

CLIENT CASES

► Knowlegde of all sealing types

► FEM analysis capabilitys

► 3D design department

► Material laboratory

► Prototype machining equipment

► 3D ”rubber” printing options

► Custom made reverse engineering equipment

1. PERFECT SEALING SURFACE

2. O-Rings Class A+

3. Oil Reduction Rod Seal Improvement

4. One piece Oil Seal Design

CONTACT FORM

We believe in the quality of our products and service. Fill out the form and one of our skilled engineers will contact you.

NewDealSeals

+31 (0) 226 362 233

Energiestraat 2-5, 1749 DN Warmenhuizen, The Netherlands