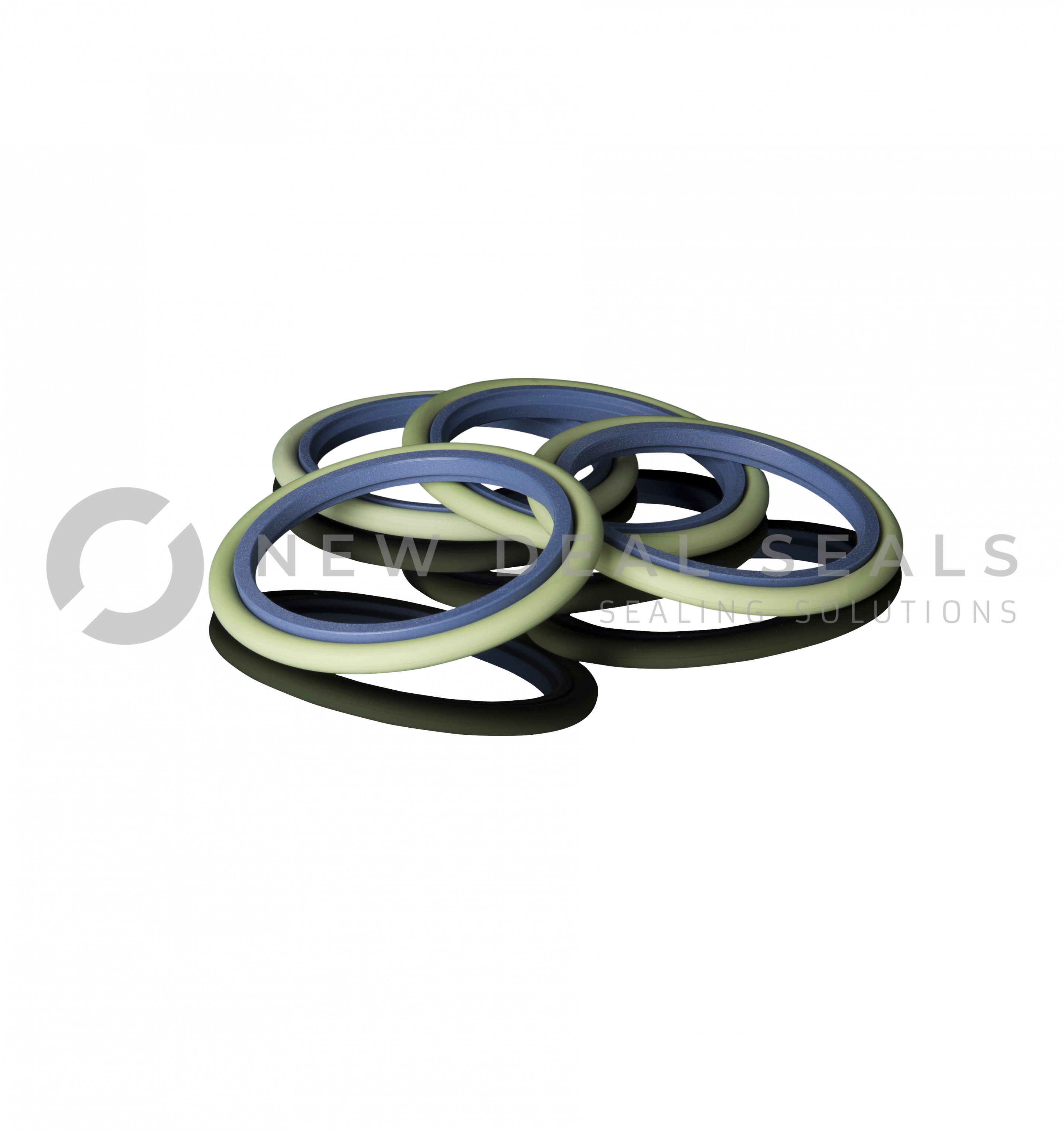

Rod Seals

Rod seals are used in hydraulic applications to seal liquids inside cylinders. Rod seals are mounted externally. They seal the cylinder rod and prevent liquid from leaking out of the cylinder.

NewDealSeals supplies a wide range of hydraulic rod seals as an economic alternative to e.g. AQ Seal®, Bal Seal®, Double Delta®, Flexiseal®, Glyd Ring®, MSE® Seal, Omniseal®, Rimseal®, Stepseal®, VL Seal®, Variseal® and Wynseal®.

Advantages Rod Seal

- Minimal break-out and dynamic slide friction. Therefore no stick-slip. Steady movement is guaranteed even at low velocities.

- Low wear.

- High extrusion resistance.

- High temperature resistance.

- Compatibility with nearly all media due to the high chemical resistance of the rod sealing ring, and a wide selection of O-ring compounds.

- Available in diameters up to 1500 mm.

Technical Specifications

Movement type

Rotary, reciprocating

Working pressure

Standard:≤ 400 bar (≤ 160 bar for profile R3)

In case of reduced extrusion gap (H7/f7) and large cross-sections:≤ 600 bar

Working temperature

Standard:-30 to +108° C

With FKM O-Ring: -25 to +204° C

Surface speed

≤ 4,0 m/s

Standard compounds Rod Seal

NDS-150, PTFE modified. NDS-660, PTFE + 60% bronze

Standard materials O-ring

NBR, FKM

Profiles Rod Seals

PROFILE R1

Single acting for hydraulic cylinders

Profile R1 is particularly suitable for rods in control cylinders, servo-assisted equipment, machine tools and quick acting cylinders. An optimal sealing performance is obtained if the sealing set is used in tandem with a double-wiper.

Advantage compared to R2 & R3:

Good back-transport of oil film due to special shape of sealing edge.

PROFILE R2

Double-acting for hydraulic cylinders

Profile R2 is particularly suitable for rods in control cylinders, servo-assisted equipment, machine tools, quick acting cylinders and in construction machinery.

Advantage compared to R1 & R3:

Capable of sealing dynamic pressure from both sides (bidirectional) at high pressure.

PROFILE R3

Double-acting for hydraulic cylinders

Profile R3 is appropriate for dynamic applications as an alternative to an O-ring, for situations where sealing performance and friction have to be optimised.

Advantage compared to R1 & R2:

Can be used in existing O-ring grooves.

PTFE COMPOUNDS

| Color | Temperature | Application | Information | |

|---|---|---|---|---|

| NDS-100 PTFE-virgin |

White | -190 to +230 °C | Chemical Industry, Food Industry | High chemical resistance Datasheet |

| NDS-123 PTFE +15% glass, +5% molybdenum disulfide |

Grey | -190 to +290 °C | Medium-duty |

High chemical resistance, High creep resistance, Electrical properties like virgin PTFE

|

| NDS-225 PTFE +25% carbon |

Black | -190 to +315 °C | Pneumatics Rotary sealing | High wear and creep resistance Datasheet |

| NDS-235 PTFE +10% carbon fibre |

Black | -260 to +310 °C | Water hydraulics, Seawater, Short strokes with high frequency | Very good wear properties Datasheet |

| NDS-415 PTFE +15% graphite |

Antrachite | -190 to +230 °C | Low mechanical stress, Soft sealing Surfaces | Chemical resistance |

| NDS-555 PTFE + mineral fibers |

Antrachite | -200 to +260 °C | Medium and heavy mechanical stress, Hydraulic applications | Chemical, wear and creep resistance Datasheet |

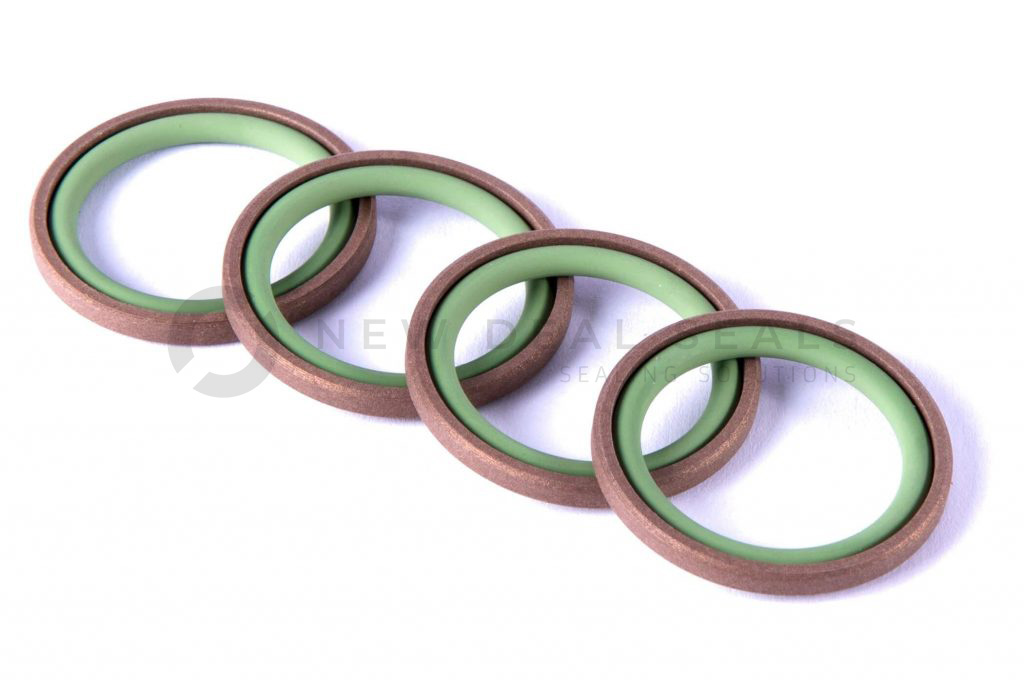

| NDS-640 PTFE +40% bronze |

Bronze | -156 to +260 °C | Medium and heavy mechanical stress, Hydraulic applications |

Outstanding wear and creep resistance

|

| NDS-660 PTFE +60% bronze |

Bronze | -156 to +260 °C | Heavy mechanical stress, Hydraulic applications | Outstanding wear and creep resistance |

| NDS-750 PTFE + polyimide |

Tan | -260 to +310 °C | High speed rotating applications | Use against soft metals |

Related PTFE Seals

Back-up Rings

Back-up rings are used for static and dynamic applications in connection with O-rings, to prevent extrusion of the O-ring into the diametrical clearance.

Rotary Seals

Rotary seals are used in applications with oscillating or rotating movements in order to retain liquid lubricants and to prevent the penetration of dirt and water.

Piston Seals

The Piston Seal consists of a single-acting PTFE piston sealing ring and an O-ring. They are combined as a single unit and are appropriate for single- acting pistons in hydraulic cylinders.

CONTACT FORM

We believe in the quality of our products and service. Fill out the form on the right-hand side and we will contact you shortly. Or you can use our product request form here.

NewDealSeals B.V.

+31 (0) 226 362 233

Boezemschop 8, Breekland, 1724 BJ Oudkarspel, The Netherlands