MOLDED RUBBER PARTS

Our wide range of rubber sealing parts can usually provide a reliable sealing solution. In some cases it is however needed to design a custom made sealing solution. Molded Rubber Parts provide the perfect solution for these advanced sealing problems.

Our product engineers work together with our customers’ engineering teams to develop and test these new sealing solutions.

Due to our experience with rubber (elastomers), PTFE and other innovative plastics and metal, including metal bonded to rubber parts we can further optimize the design and assembly.

Our goal has been the same since day one. To make sure YOU the customer are completely satisfied. Our product engineers are available to assist you in any way. Would you like to know what we can do for you?

COMMON RUBBER PARTS

Rubber Grommets

Rubber grommets are used to protect wires, cables or cords from rough edges or cutouts.

Rubber Bushings

Rubber bushings are used to absorb shocks and to reduce noise/vibrations between parts.

Rubber Bumpers & Stops

Rubbers Bumpers and stops are used to protect parts from scratches, impact and abrasion.

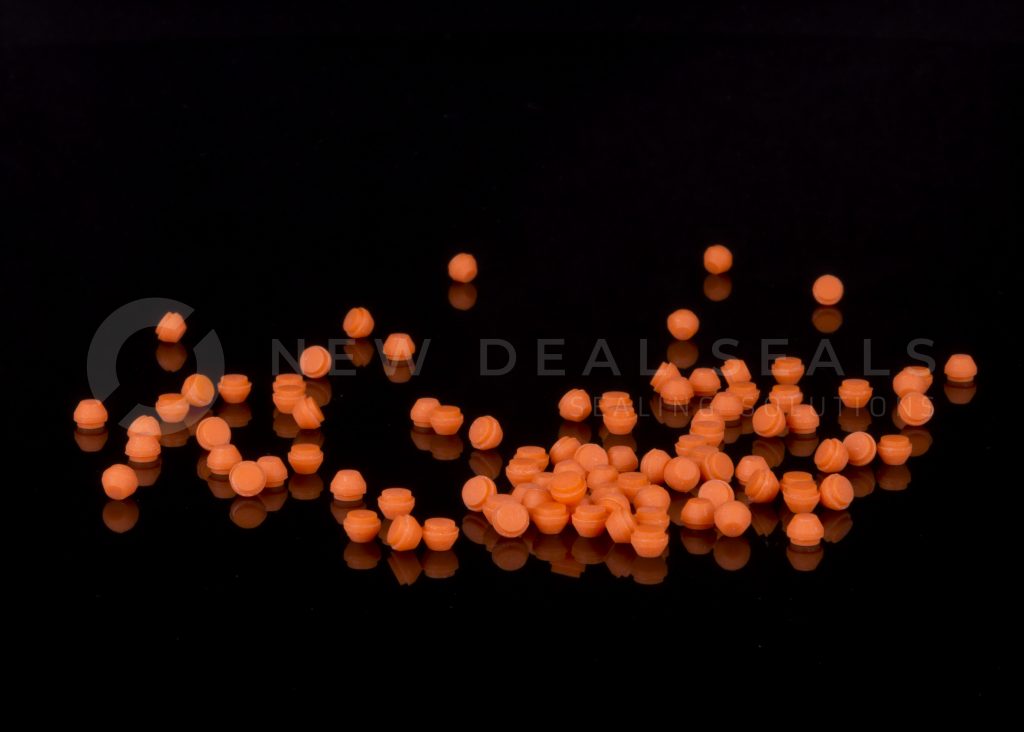

Rubber Caps & Plugs

Rubber caps and plugs are used to protect parts from dust, dirt and other possible contaminations.

Rubber Bellows

Rubber bellows are used to protect both static and moving parts from dust, dirt and oil. The bellow shape makes these seals highly flexible.

Rubber to Metal bonded parts

Bonding rubber to metal is a reliable way to permanently mount rubber to metal. Rubber to metal bonded parts are commonly used as shock absorbers or vibration dampers.

RUBBER COMPOUNDS

NewDealSeals supplies Rubber products in more than 500 different rubber compounds. NewDealSeals has a polymer laboratory specialized in the development of custom compounds, reverse compound engineering and failure analysis.

WE WORK WITH A VARIETY OF MATERIALS, INCLUDING:

- NBR (Buna N, Perbunan®)

- EPDM/EPM (Buna EP®, Keltan®, Nordel®, Vistalon®)

- FKM/FPM (Viton®, Dyneon®, Tecnoflon®, DAI-EL®)

- FVMQ (FE®, Silastic LS®)

- FFKM (Fluorezi®, Kalrez®, Isolast®, Ultra®, Simriz®)

- VMQ (Siliastic®, Silplus®)

CUSTOM COMPOUNDING OF:

- Mechanical properties

- Chemical resistance

- Temperature resistance

- Colour

WHY NEWDEALSEALS

Good cooperation is an absolute requirement for the successful development of rubber molded parts. NewDealSeals is very aware with our active involvement, transparency, honest- and knowledgeable advice. Our proactive attitude leads to a better result, that benefits you as a customer and us as a supplier.

SERVICES:

- Product design, development & engineering

- Co-engineering & reverse engineering

- 3D modeling & engineering analyses

MANUFACTURING OPTIONS:

- Injection molding

- Compression molding

- Material combinations (rubber, PTFE and metal)

CLIENT CASES

► Knowlegde of all sealing types

► FEM analysis capabilitys

► 3D design department

► Material laboratory

► Prototype machining equipment

► 3D ”rubber” printing options

► Custom made reverse engineering equipment

1. PERFECT SEALING SURFACE

2. O-Rings Class A+

3. Oil Reduction Rod Seal Improvement

4. One piece Oil Seal Design

CONTACT FORM

We believe in the quality of our products and service. Fill out the form on the right-hand side and we will contact you shortly. Or you can use our product request form here.

NewDealSeals B.V.

+31 (0) 226 362 233

Boezemschop 8, Breekland, 1724 BJ Oudkarspel, The Netherlands