SYNERINGS®

The Synering® system is an advanced sealing concept designed to meet extreme demands regarding temperature, medium, etc. which cannot be covered by conventional sealing compounds (like elastomers, PUR, fabric materials, etc.)

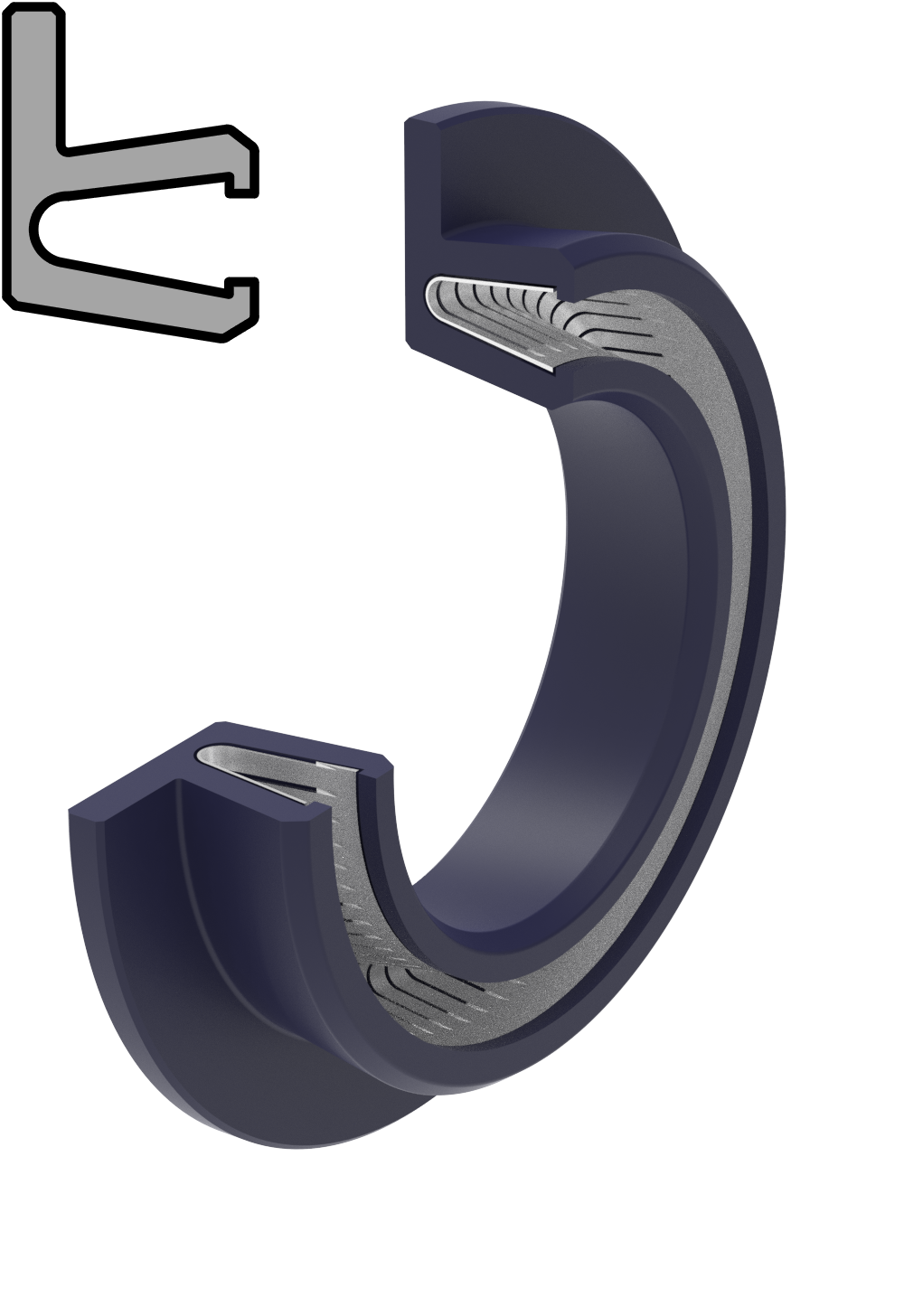

PTFE is hardly elastic. Therefore, PTFE sealing elements have to be combined with an elastic component, usually an O-ring. Synerings® consist of a PTFE part, made of a specially modified compound, and an energizing spring (standard: stainless steel). So, the outstanding thermal and chemical properties of PTFE can be used to full advantage.

NewDealSeals supplies a wide range of spring-energized seals as an economic alternative to for instance Balseal®, Flexiseal®, Omniseal® and Variseal®.

HOW DOES THE SYNERING® WORK?

The Synering® is an advanced seal designed for extreme environments where conventional seals fail. Its unique design combines a PTFE element with exceptional chemical and thermal resistance with a booster spring for consistent sealing force.

How it Works:

- Installation: The Synering® is radially or axially mounted.

- Initial Sealing: The spring activates the sealing lips for a positive seal, even without system pressure.

- Pressure Increase: System pressure further activates the seal, increasing sealing force.

- Dynamic Applications: During movement, the spring compensates for wear and maintains a tight seal.

- Thermal Cycling: The spring retains its force and continuously activates the seal under temperature fluctuations.

Benefits:

- Excellent chemical and thermal resistance

- High and consistent sealing force

- Reduced wear and extended service life

- Accommodates slight alignment and tolerance variations

TECHNICAL SPECIFICATIONS

OPERATING TEMPERATURES

Synerings® with V-spring: -150 to + 225°C

Synerings® with O-spring: -150 to + 260°C

OPERATION VELOCITIES

Synerings® with V-spring

Reciprocating: 15-20 m/s

Helical and rotating: ≤ 4 m/s

Synerings® with O-spring

Reciprocating: 15-20 m/s

Helical and rotating: ≤ 4 m/s

PRESSURE LIMITS

Synerings® with V-spring: ≤ 350 bar

Synerings® with O-spring: ≤ 800 bar

PROFILES

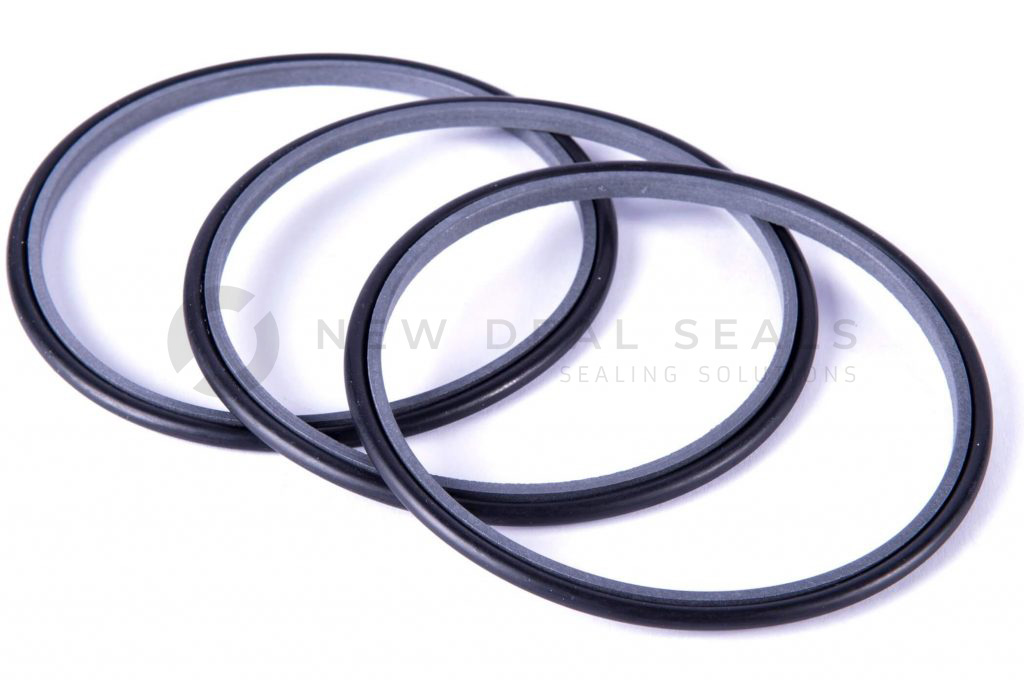

PROFILE S1

Rotating

The profile S1 consists of a PTFE sealing ring with a V-spring. The profile S1 is appropriate for rotating applications as an alternative to an O-ring in situations where sealing performance and friction have to be optimized.

PROFILE S2

Dynamic rod sealing

The profile S2 consists of a PTFE sealing ring with a V-spring. The profile S2 is appropriate for dynamic rod sealing applications as an alternative to an O-ring in situations where sealing performance and friction have to be optimized.

PROFILE S3

Dynamic piston sealing

The profile S3 consists of a PTFE sealing ring with a V-spring. The profile S3 is appropriate for dynamic piston sealing applications as an alternative to an O-ring in situations where sealing performance and friction have to be optimized.

PROFILE S4

Static inside sealing

The profile S4 consists of a PTFE sealing ring with an O-spring. The profile S4 is appropriate for static inside sealing applications as an alternative to an O-ring in situations where sealing performance has to be optimized.

PROFILE S5

Static outside sealing

The profile S5 consists of a PTFE sealing ring with an O-spring. The profile S5 is appropriate for static outside sealing applications as an alternative to an O-ring in situations where sealing performance has to be optimized.

PROFILE S6

Flange sealing: internal pressure

The profile S6 consists of a PTFE sealing ring with an O-spring. The profile S6 is appropriate for flange sealing applications with internal pressure as an alternative to an O-ring in situations where sealing performance has to be optimized.

PROFILE S7

Flange sealing: external pressure

The profile S7 consists of a PTFE sealing ring with an O-spring. The profile S7 is appropriate for flange sealing applications with external pressure as an alternative to an O-ring in situations where sealing performance has to be optimized.

PTFE COMPOUNDS

| Color | Temperature | Application | Information | |

|---|---|---|---|---|

| NDS-100 PTFE-virgin |

White | -190 to +230 °C | Chemical Industry, Food Industry | High chemical resistance Datasheet |

| NDS-123 PTFE +15% glass, +5% molybdenum disulfide |

Grey | -190 to +290 °C | Medium-duty |

High chemical resistance, High creep resistance, Electrical properties like virgin PTFE

|

| NDS-225 PTFE +25% carbon |

Black | -190 to +315 °C | Pneumatics Rotary sealing | High wear and creep resistance Datasheet |

| NDS-235 PTFE +10% carbon fibre |

Black | -260 to +310 °C | Water hydraulics, Seawater, Short strokes with high frequency | Very good wear properties Datasheet |

| NDS-415 PTFE +15% graphite |

Antrachite | -190 to +230 °C | Low mechanical stress, Soft sealing Surfaces | Chemical resistance |

| NDS-555 PTFE + mineral fibers |

Antrachite | -200 to +260 °C | Medium and heavy mechanical stress, Hydraulic applications | Chemical, wear and creep resistance Datasheet |

| NDS-640 PTFE +40% bronze |

Bronze | -156 to +260 °C | Medium and heavy mechanical stress, Hydraulic applications |

Outstanding wear and creep resistance

|

| NDS-660 PTFE +60% bronze |

Bronze | -156 to +260 °C | Heavy mechanical stress, Hydraulic applications | Outstanding wear and creep resistance |

| NDS-750 PTFE + polyimide |

Tan | -260 to +310 °C | High speed rotating applications | Use against soft metals |

Related PTFE Seals

Back-up Rings

Back-up rings are used for static and dynamic applications in connection with O-rings, to prevent extrusion of the O-ring into the diametrical clearance.

Rotary Seals

Rotary seals are used in applications with oscillating or rotating movements in order to retain liquid lubricants and to prevent the penetration of dirt and water.

Rod Seals

The Rod Seal consists of a single-acting PTFE rod sealing ring and an O-ring. They are combined as a single unit and are appropriate for rods and plungers in hydraulic cylinders.

CONTACT FORM

We believe in the quality of our products and service. Fill out the form on the right-hand side and we will contact you shortly. Or you can use our product request form here.

NewDealSeals B.V.

+31 (0) 226 362 233

Boezemschop 8, Breekland, 1724 BJ Oudkarspel, The Netherlands